Executive Order EO 13972.

Section 1. Purpose. Nuclear energy is critical to United States national security. That is why I have taken a series of actions to promote its development and facilitate its use. On June 29, 2017, I announced an initiative to revive and expand the nuclear energy sector and directed a complete review of United States nuclear energy policy to help find new ways to revitalize this crucial energy resource. On July 12, 2019, I signed a Presidential Memorandum entitled “The Effect of Uranium Imports on the National Security and Establishment of the United States Nuclear Fuel Working Group,” with the goal of examining the current state of domestic nuclear fuel production and reinvigorating the nuclear fuel supply chain, consistent with United States national security and nonproliferation goals. On August 20, 2019, I signed National Security Presidential Memorandum-20, entitled “Launch of Spacecraft Containing Space Nuclear Systems,” calling for development and use of space nuclear systems to enable or enhance space exploration and operational capabilities.

The purpose of this order is to take an important additional step to revitalize the United States nuclear energy sector, reinvigorate America’s space exploration program, and develop diverse energy options for national defense needs. Under this action, the United States Government will coordinate its nuclear activities to apply the benefits of nuclear energy most effectively toward American technology supremacy, including the use of small modular reactors for national defense and space exploration. This work is critical to advancing my Administration’s priorities for the United States to lead in research, technology, invention, innovation, and advanced technology development; its mission to promote and protect the United States national security innovation base; its drive to secure energy dominance; and its commitment to achieving all of these goals in a manner consistent with the highest nuclear nonproliferation standards.

The United States was the first nation to invent and develop the technology to harness nuclear energy. Since the 1950s, the United States Navy has been operating and advancing transportable nuclear reactors, resulting in powerfully enhanced marine propulsion for its aircraft carriers and allowing nuclear-powered submarines to remain submerged for extended periods of time.

The United States must sustain its ability to meet the energy requirements for its national defense and space exploration initiatives. The ability to use small modular reactors will help maintain and advance United States dominance and strategic leadership across the space and terrestrial domains.

Sec. 2. Policy. It is the policy of the United States to promote advanced reactor technologies, including small modular reactors, to support defense installation energy flexibility and energy security, and for use in space exploration, guided by the following principles:

(a) A healthy and robust nuclear energy industry is critical to the national security, energy security, and economic prosperity of the United States;

(b) The United States should maintain technology supremacy for nuclear research and development, manufacturing proficiency, and security and safety;

(c) The United States Government should bolster national defense and space exploration capabilities and enable private-sector innovation of advanced reactor technologies.

Sec. 3. Demonstration of Commercial Reactors to Enhance Energy Flexibility at a Defense Installation. (a) Micro-reactors have the potential to enhance energy flexibility and energy security at domestic military installations in remote locations. Accordingly, the Secretary of Defense shall, within 180 days of the date of this order, establish and implement a plan to demonstrate the energy flexibility capability and cost effectiveness of a Nuclear Regulatory Commission-licensed micro‑reactor at a domestic military installation.

(b) If the demonstration is successful, the Secretary of Defense shall identify opportunities at domestic military installations where this capability could enhance or supplement the fulfillment of installation energy requirements. In identifying these opportunities, the Secretary of Defense shall take into account considerations that are unique to national defense needs and requirements that may not be relevant in the private sector, such as:

(i) the ability to provide resilient, independent energy delivery to installations in the event that connections to an electrical grid are compromised;

(ii) the ability to operate for an extended period of time without refueling;

(iii) system resistance to disruption from an electro‑magnetic pulse event; and

(iv) system cybersecurity requirements.

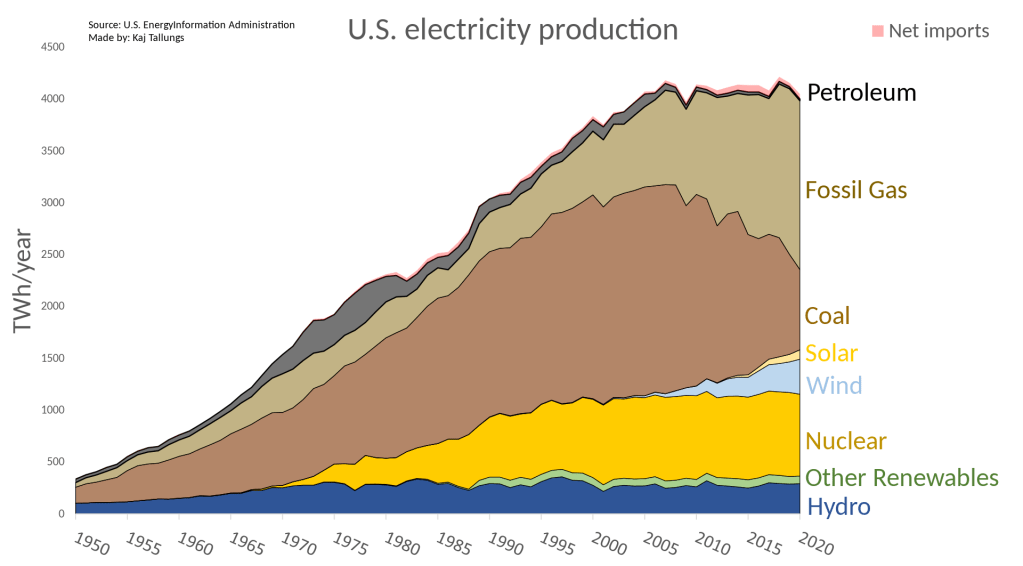

Sec. 4. Defense Capabilities. (a) The Department of Defense is one of the largest consumers of energy in the world, using more than 10 million gallons of fuel per day and 30,000 gigawatt-hours of electricity per year, nearly all of which is provided through civilian electrical grids. Fuel demands for a modern United States military have dramatically grown since World War II and are anticipated to continue to increase in order to support high-energy-usage military systems. In this context, nuclear power could significantly enhance national defense power capabilities.

(b) The Secretary of Defense shall, in consultation with the Secretary of State, the Secretary of Commerce, the Secretary of Energy, and the Administrator of the National Aeronautics and Space Administration (NASA Administrator):

(i) determine whether advanced nuclear reactors can be made to benefit Department of Defense future space power needs;

(ii) pilot a transportable micro-reactor prototype;

(iii) direct an analysis of alternatives for personnel, regulatory, and technical requirements to inform future decisions with respect to nuclear power usage; and

(iv) direct an analysis of United States military uses for space nuclear power and propulsion technologies and an analysis of foreign adversaries’ space power and propulsion programs.

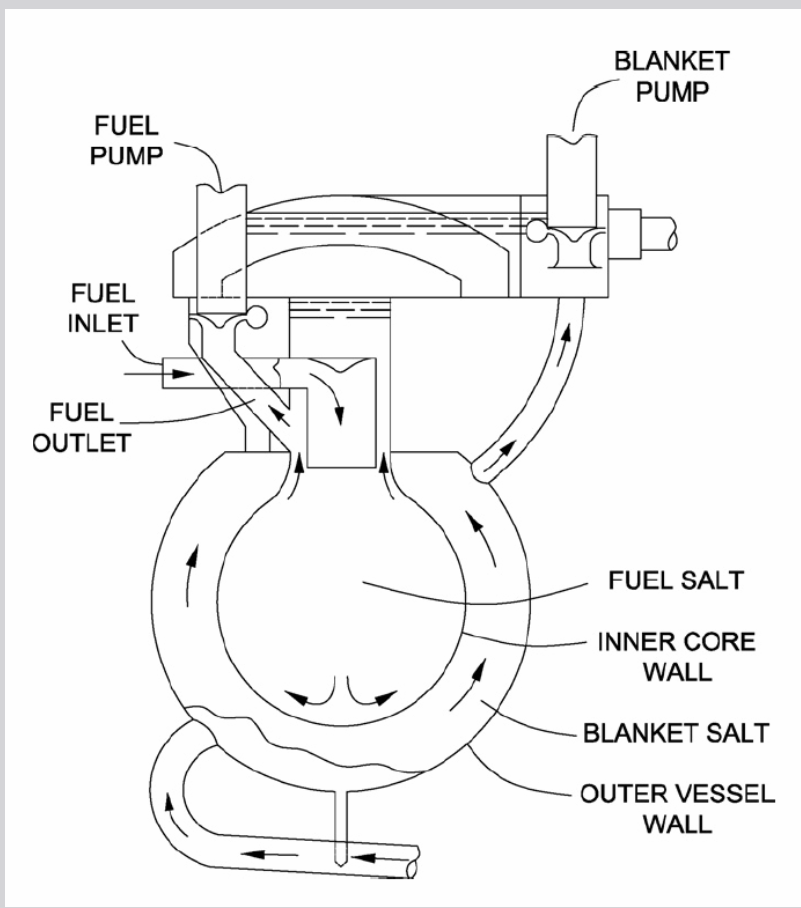

Sec. 5. Space Exploration. (a) Nuclear power sources that use uranium fuel or plutonium heat sources are essential to deep space exploration and in areas where solar power is not practical. NASA uses radioisotope power systems, such as radioisotope thermoelectric generators and radioisotope heater units, to provide power and heat for deep space robotic missions. Nuclear power sources in the kilowatt range may be needed for demonstrating In-situ Resource Utilization (ISRU) and robotic exploration of permanently shadowed craters on the Moon that contain frozen water. Nuclear reactors up to 100 kilowatts may be needed to support human habitats, ISRU, other facilities, and rovers on both the Moon and Mars. Power sources in the megawatt range would be necessary for efficient, long‑duration deep space propulsion. Affordable, lightweight nuclear power sources in space would enable new opportunities for scientific discovery. The sustainable exploration of the Moon, Mars, and other locations will be enhanced if small modular reactors can be deployed and operated remotely from Earth.

(b) Within 180 days of the date of this order, the NASA Administrator, in consultation with heads of other executive departments and agencies (agencies), as appropriate, shall define requirements for NASA utilization of nuclear energy systems for human and robotic exploration missions through 2040 and analyze the costs and benefits of such requirements. In defining these requirements, the NASA Administrator shall take into account considerations unique to the utilization of nuclear energy systems in space, such as:

(i) transportability of a reactor prior to and after deployment;

(ii) thermal management in a reduced- or zero-gravity environment in a vacuum or near-vacuum;

(iii) fluid transfer within reactor systems in a reduced or zero-gravity environment;

(iv) reactor size and mass that can be launched from Earth and assembled in space;

(v) cooling of nuclear reactors in space;

(vi) electric power requirements

(vii) space safety rating to enable operations as part of human space exploration missions;

(viii) period of time for which a reactor can operate without refueling; and

(ix) conditioning of reactor components for use in the space environment.

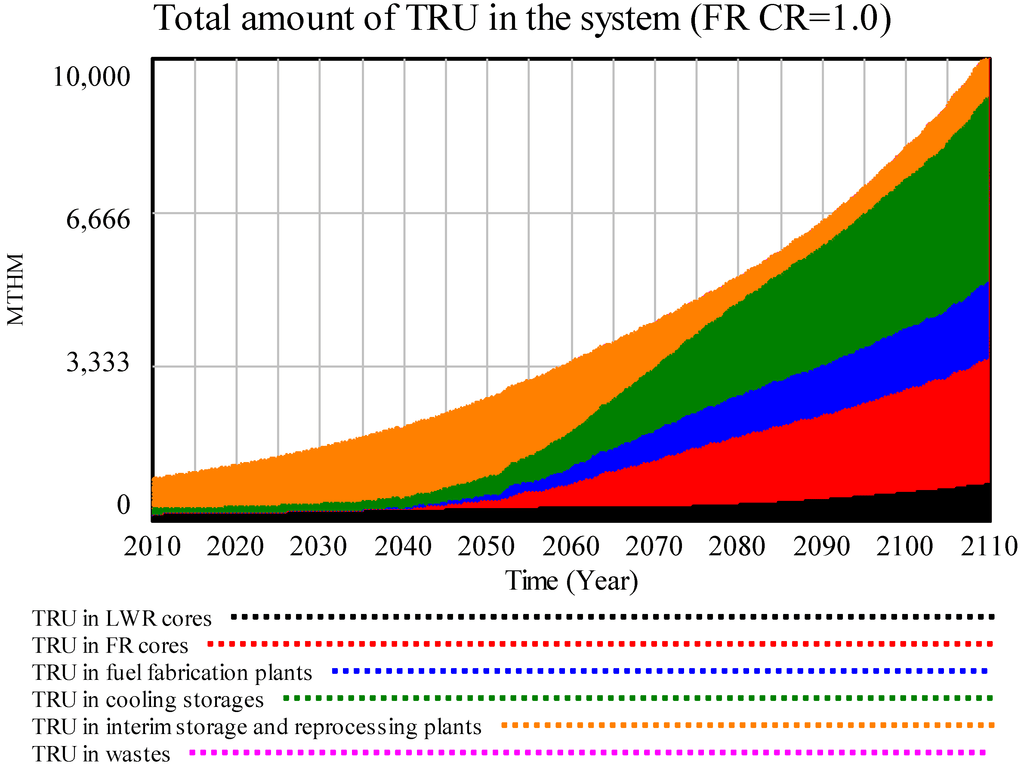

Sec. 6. Domestic Fuel Supply. (a) A thriving and secure domestic nuclear fuel supply chain is critical to the national interests of the United States. A viable domestic nuclear fuel supply chain not only supports defense and national security activities, but also enables the success of the commercial nuclear industry. Many advanced reactor concepts, however, will require high-assay, low-enriched uranium (HALEU), for which no domestic commercial enrichment capability currently exists. The United States must take steps to ensure a viable United States-origin HALEU supply.

(b) The Secretary of Energy shall complete the Department of Energy’s ongoing 3-year, $115 million demonstration of a United States-origin enrichment technology capable of producing HALEU for use in defense-related advanced reactor applications. Within funding available for the demonstration project, the Secretary of Energy should develop a plan to promote successful transition of this technology to the private sector for commercial adoption.

(c) The Secretary of Energy shall consult with the Secretary of Defense, the Director of the Office of Management and Budget, and the NASA Administrator regarding how advanced fuels and related technologies can best support implementation of sections 3, 4, and 5 of this order.

Sec. 7. Common Technology Roadmap. (a) The Secretary of State, the Secretary of Defense, the Secretary of Commerce, the Secretary of Energy, and the NASA Administrator shall develop a common technology roadmap through 2030 that describes potential development programs and that coordinates, to the extent practicable, terrestrial-based advanced nuclear reactor and space-based nuclear power and propulsion efforts. Agencies shall remain responsible for funding their respective mission-unique requirements. The roadmap shall also include, at a minimum:

(i) assessments of foreign nations’ space nuclear power and propulsion technological capabilities;

(ii) pathways for transitioning technologies developed through Federally supported programs to private-sector activities; and

(iii) other applications supporting the goals provided in section 1 of this order.

(b) The roadmap shall be submitted to the President by the Director of the Office of Management and Budget, the Assistant to the President for Domestic Policy, the Director of the Office of Science and Technology Policy, the Assistant to the President for National Security Affairs, the Assistant to the President for Economic Policy, and the Executive Secretary of the National Space Council before submissions of budget proposals by the Secretary of State, the Secretary of Commerce, the Secretary of Energy, and the NASA Administrator.

Sec. 8. Definitions. For purposes of this order:

(a) The term “small modular reactor” refers to an advanced nuclear reactor of electric generation capacity less than 300 megawatt-electric. Because of the smaller size, small modular reactors can generally be designed for factory fabrication and modular construction to take advantage of economies of serial production and shorter construction times.

(b) The term “micro-reactor” refers to a nuclear reactor of electric generation capacity less than 10 megawatt-electric that can be deployed remotely. Micro-reactors are a subset of small modular reactors and are also known as “very small modular reactors.”

(c) The term “transportable micro-reactor” refers to a micro-reactor that can be moved by truck, ship, or large military transport aircraft and is capable of both rapid deployment and teardown or removal, typically with safe teardown or removal less than 1 week after 1 year of full-power operation.

(d) The term “space exploration” refers to in-space scientific and resource exploration, in-space economic and industrial development, and development of associated in-space logistical infrastructure.

(e) The term “national defense” refers to the protection of the United States and its interests from foreign attack or other natural danger, including phenomena occurring on Earth and in space.

Sec. 9. General Provisions. (a) Nothing in this order shall be construed to impair or otherwise affect:

(i) the authority granted by law to an executive department or agency, or the head thereof; or

(ii) the functions of the Director of the Office of Management and Budget relating to budgetary, administrative, or legislative proposals.

(b) This order shall be implemented consistent with applicable law and subject to the availability of appropriations.

(c) This order is not intended to, and does not, create any right or benefit, substantive or procedural, enforceable at law or in equity by any party against the United States, its departments, agencies, or entities, its officers, employees, or agents, or any other person.

DONALD J. TRUMP

THE WHITE HOUSE,

January 5, 2021. WhiteHouse.gov