The Generation IV International Forum’s current membership consists of:

| Argentina* |  | Japan | ||

| Australia |  | Republic of Korea | |||

| Brazil* |  | Russian Federation | ||

| Canada |  | Republic of South Africa | ||

| People’s Republic of China |  | Switzerland | ||

| Euratom |  | United Kingdom | ||

| France |  | United States |

The list of possible implementations is long and growing, Here are most of them: Most of them can operate on Uranium or Plutonium or mixed fuel including a fertile blanket of Thorium that converts to U-233 as fissile material. The remaining problem is the clean extraction of fission products and protactinium during full operation. In the mean time they will help generate enough U-233 for clean operation with minimum waste production.

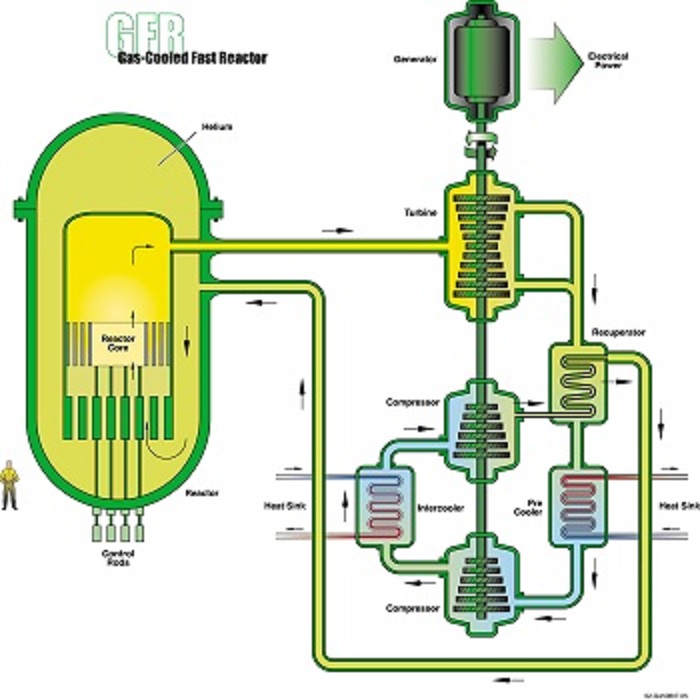

Gas-Cooled Fast Reactor (GFR)

The GFR system is a high-temperature (850C) helium-cooled fast-spectrum reactor with a closed fuel cycle. It combines the advantages of fast-spectrum systems for long-term sustainability of uranium resources and waste minimization (through fuel multiple reprocessing and fission of long-lived actinides), with those of high-temperature systems (high thermal cycle efficiency and industrial use of the generated heat, for hydrogen production for example).

This system is ideal for co-generation of electricity and hydrogen production.

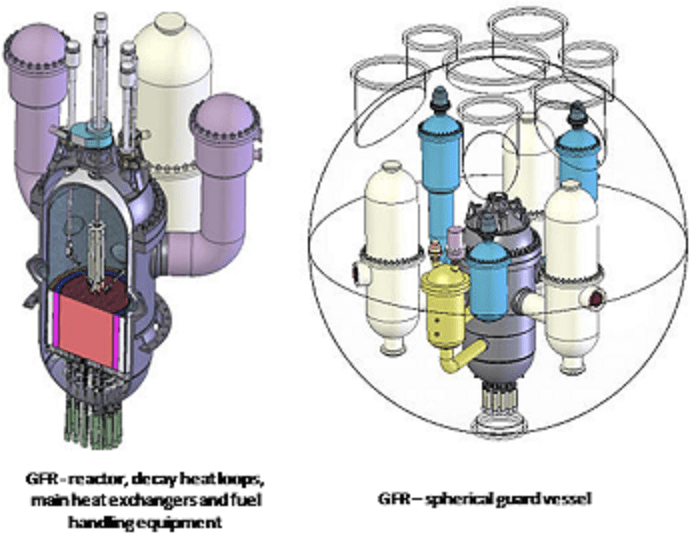

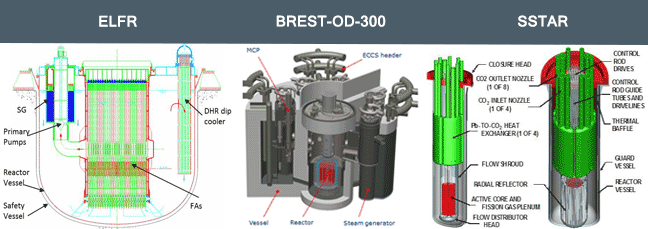

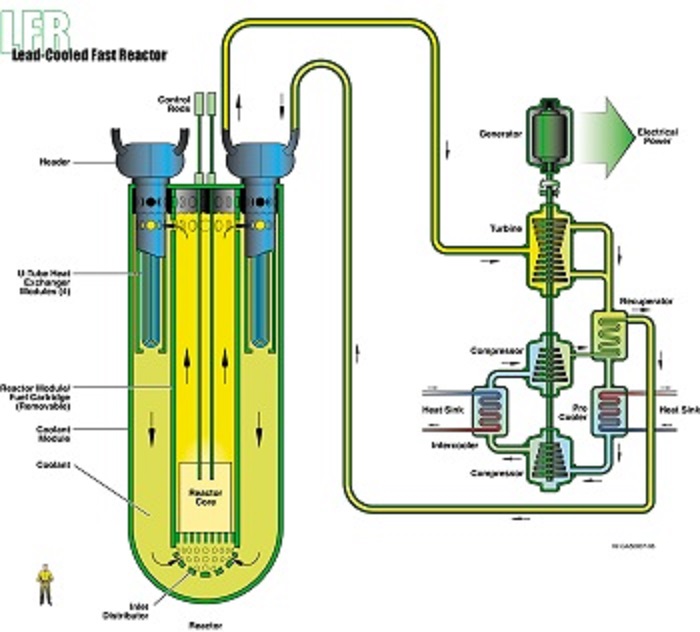

Lead-Cooled Fast Reactor (LFR)

a

This reactor type would have multiple applications including production of electricity, hydrogen and process heat. System concepts represented in plans of the Generation IV International Forum (GIF) System Research Plan (SRP) are based on Europe’s ELFR lead-cooled system, Russia’s BREST-OD-300 and the SSTAR system concept designed in the US. Numerous additional LFR concepts are also under various stages of development in different countries including China, Russia, the USA, Sweden, Korea and Japan.

Molten Salt Reactor (MSR)

. The onsite fuel reprocessing unit using pyrochemistry allows breeding plutonium or uranium-233 from Thorium.

Compared with solid-fuel reactors, MSFR systems have lower fissile inventories, no radiation damage constraint on attainable fuel burn-up, no requirement to fabricate and handle solid fuel, and a homogeneous isotopic composition of fuel in the reactor. These and other characteristics give MSFRs potentially unique capabilities for actinide burning and extending fuel resources.

MSR developments in Russia on the Molten Salt Actinide Recycler and Transmuter (MOSART) aim to be used as efficient burners of transuranic (TRU) waste from spent UOX and MOX light water reactor (LWR) fuel without any uranium and thorium support and also with it. Other advanced reactor concepts are being studied, which use the liquid salt technology, as a primary coolant for Fluoride salt-cooled High-temperature Reactors (FHRs), and coated particle fuels similar to high temperature gas-cooled reactors.

More generally, there has been a significant renewal of interest in the use of liquid salt as a coolant for nuclear and non-nuclear applications. These salts could facilitate heat transfer for nuclear hydrogen production concepts, concentrated solar electricity generation, oil refineries, and shale oil processing facilities amongst other applications.

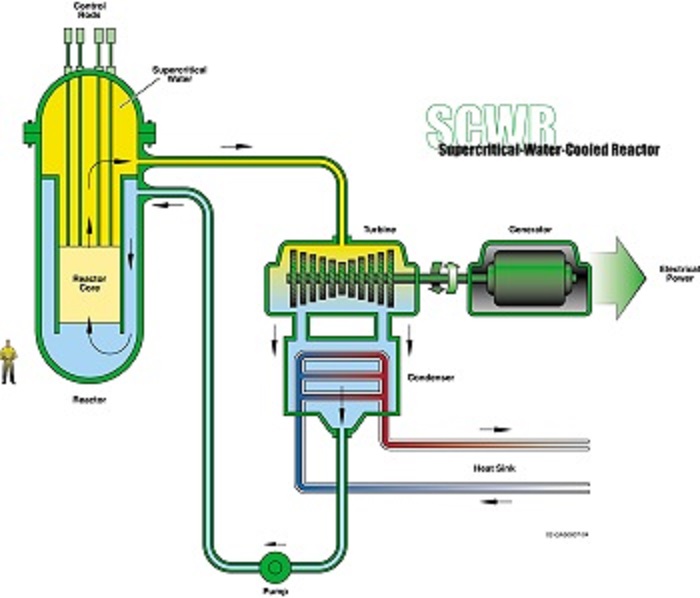

Supercritical-Water-Cooled Reactor (SCWR)

SCWRs are high temperature, high-pressure, light-water-cooled reactors that operate above the thermodynamic critical point of water (374°C, 22.1 MPa).

SCWR designs have unique features that offer many advantages compared to state-of the-art water-cooled reactors:

- SCWRs offer increases in thermal efficiency relative to current-generation water-cooled reactors. The efficiency of a SCWR can approach 44% or more, compared to 34-36% for current reactors.

- Reactor coolant pumps are not required. The only pumps driving the coolant under normal operating conditions are the feed water pumps and the condensate extraction pumps.

- The steam generators used in pressurized water reactors and the steam separators and dryers used in boiling water reactors can be omitted since the coolant is superheated in the core.

- Containment, designed with pressure suppression pools and with emergency cooling and residual heat removal systems, can be significantly smaller than those of current water-cooled reactors.

- The higher steam enthalpy allows to decrease the size of the turbine system and thus to lower the capital costs of the conventional island.

There remains a number of challenges before this approach can be fully implemented, and one limiting factor is composite materials that can withstand high pressure, high temperature and high radiation at the same time.

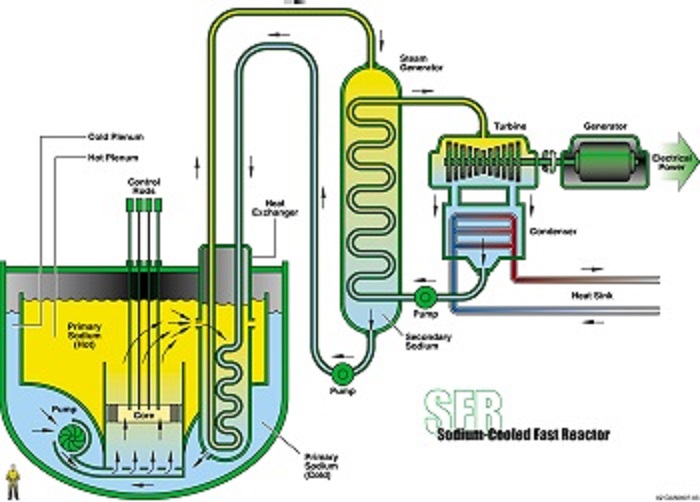

Sodium-Cooled Fast Reactor (SFR)

|

The SFR uses liquid sodium as the reactor coolant, allowing high power density with low coolant volume fraction and operation at low pressure. While the oxygen-free environment prevents corrosion, sodium reacts chemically with air and water and requires a sealed coolant system.

Plant size options under consideration range from small, 50 to 300 MWe, modular reactors to larger plants up to 1 500 MWe. The outlet temperature is 500-550°C for the options, which allows the use of the materials developed and proven in prior fast reactor programs.

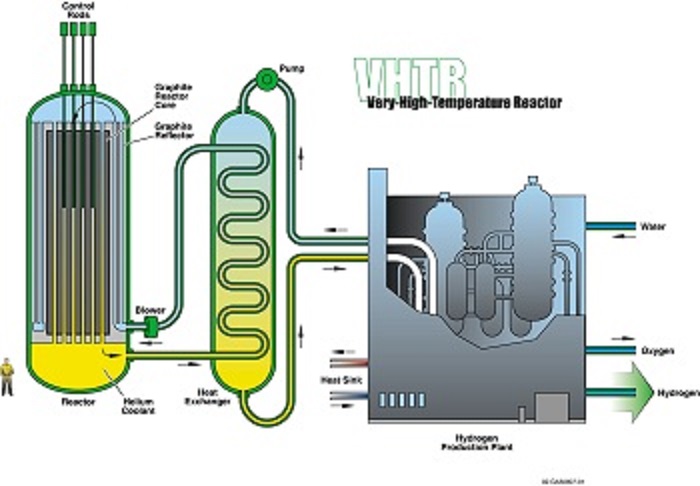

Very-High-Temperature Reactor (VHTR)

|

The VHTR is a next step in the evolutionary development of high-temperature gas-cooled reactors. It is a graphite-moderated, helium-cooled reactor with thermal neutron spectrum. It can supply nuclear heat and electricity over a range of core outlet temperatures between 700 and 950°C, or more than 1 000°C in future. The reactor core type of the VHTR can be a prismatic block core such as the Japanese HTTR, or a pebble-bed core such as the Chinese HTR-10.

The VHTR can support alternative fuel cycles such as U-Pu, Pu, MOX (Mixed Oxide fuel), U-Thorium.

For an expanded information, see source:https://www.gen-4.org/gif/jcms/c_9492/members