China is having a massive Thorium program. The People’s Republic of China has initiated a research and development project in thorium molten-salt reactor technology. The thorium MSR efforts aims not only to develop the technology but to secure intellectual property rights to its implementation. This may be one of the reasons that the Chinese have not joined the international Gen-IV effort for MSR development, since part of that involves technology exchange. Neither the US nor Russia have joined the MSR Gen-IV effort either.

China is currently the largest emitter of CO2 and air pollutants by far, and according to the Paris accord was allowed to emit six times as much pollutants as the U.S. by 2030, being a “developing nation”. Their air quality is already among the worst in the world so something had to be done if they were to achieve world dominance by 2025 and total rule by 2030. Only Thorium can solve the pollution problem and provide the clean energy needed for the future. Regular Uranium Nuclear reactors require large amounts of water and Molten Salt Thorium reactors require little water to operate.

Geneva, Switzerland, 21 August 2018 – As the world struggles with a record-breaking heatwave, China correctly places its trust in the fuel Thorium and the Thorium Molten Salt Reactor (TMSR) as the backbone of its nation’s plan to become a clean and cheap energy powerhouse.

The question is if China will manage to build a homegrown mega export industry, or will others have capacity and will to catch up?

For China, clean energy development and implementation is a test for the state’s ability. Therefore, China is developing the capability to use the “forgotten fuel” thorium, which could begin a new era of nuclear power.

The first energy system they are building is a solid fuel molten salt reactor that achieves high temperatures to maximize efficiency of combined heat and power generation applications.

However, to fully realize thorium’s energy potential and in this way solve an important mission for China – the security of fuel supply – requires also the thorium itself to be fluid. This is optimized in the Thorium Molten Salt Reactor (TMSR).

The TMSR takes safety to an entirely new level and can be made cheap and small since it operates at atmospheric pressure, one of its many advantages. Thanks to its flexible cooling options it can basically be used anywhere, be it a desert, a town or at sea. In China this is of special interest inland, where freshwater is scarce in large areas, providing a unique way to secure energy independence.

“Everyone in the field is extremely impressed with how China saw the potential, grabbed the opportunity and is now running faster than everyone else developing this futuristic energy source China and the entire world is in a great need of.”

– Andreas Norlin, Thorium Energy World

China is not telling all they are doing on Nuclear Energy, but this news item is true:

The Shanghai Institute of Applied Physics (SINAP) – part of the Chinese Academy of Sciences (CAS) – has been given approval by the Ministry of Ecology and Environment to commission an experimental thorium-powered molten-salt reactor, construction of which started in Wuwei city, Gansu province, in September 2018.

.jpg?ext=.jpg)

A cutaway of the TMSR-LF1 reactor (Image: SINAP)

In January 2011, CAS launched a CNY3 billion (USD444 million) R&D programme on liquid fluoride thorium reactors (LFTRs), known there as the thorium-breeding molten-salt reactor (Th-MSR or TMSR), and claimed to have the world’s largest national effort on it, hoping to obtain full intellectual property rights on the technology. This is also known as the fluoride salt-cooled high-temperature reactor (FHR). The TMSR Centre at SINAP at Jiading, Shanghai, is responsible.

Construction of the 2 MWt TMSR-LF1 reactor began in September 2018 and was reportedly completed in August 2021. The prototype was scheduled to be completed in 2024, but work was accelerated.

“According to the relevant provisions of the Nuclear Safety Law of the People’s Republic of China and the Regulations of the People’s Republic of China on the Safety Supervision and Administration of Civilian Nuclear Facilities, our bureau has conducted a technical review of the application documents you submitted, and believes that your 2 MWt liquid fuel thorium-based molten salt experimental reactor commissioning plan (Version V1.3) is acceptable and is hereby approved,” the Ministry of Ecology and Environment told SINAP on 2 August.

It added: “During the commissioning process of your 2 MWt liquid fuel thorium-based molten salt experimental reactor, you should strictly implement this plan to ensure the effectiveness of the implementation of the plan and ensure the safety and quality of debugging. If any major abnormality occurs during the commissioning process, it should be reported to our bureau and the Northwest Nuclear and Radiation Safety Supervision Station in time.”

The TMSR-LF1 will use fuel enriched to under 20% U-235, have a thorium inventory of about 50 kg and conversion ratio of about 0.1. A fertile blanket of lithium-beryllium fluoride (FLiBe) with 99.95% Li-7 will be used, and fuel as UF4.

The project is expected to start on a batch basis with some online refueling and removal of gaseous fission products, but discharging all fuel salt after 5-8 years for reprocessing and separation of fission products and minor actinides for storage. It will proceed to a continuous process of recycling salt, uranium and thorium, with online separation of fission products and minor actinides. The reactor will work up from about 20% thorium fission to about 80%.

If the TMSR-LF1 proves successful, China plans to build a reactor with a capacity of 373 MWt by 2030.

As this type of reactor does not require water for cooling, it will be able to operate in desert regions. The Chinese government has plans to build more across the sparsely populated deserts and plains of western China, complementing wind and solar plants and reducing China’s reliance on coal-fired power stations. The reactor may also be built outside China in Belt and Road Initiative nations.

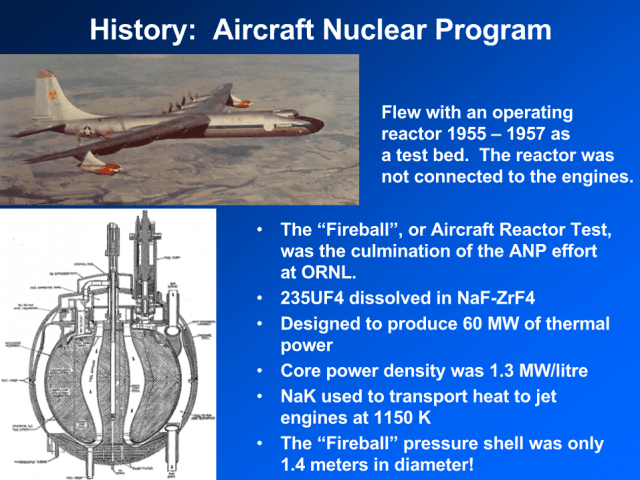

The liquid fuel design is descended from the 1960s Molten-Salt Reactor Experiment at Oak Ridge National Laboratory in the USA. (Researched and written by World Nuclear News)

Yes, it is true. Their design was given to them free, and now PRC is developing the future energy source including claiming intellectual property rights from a source abandoned in 1969 by U.S.A. because of political infighting, not for economical or national security reasons.